Recent Posts

Water Purity in Vaccine Manufacturing

Water, a fundamental component in vaccine production, plays a critical role in ensuring the safety, potency, and purity of vaccines. The stringent requirements for water purity in the pharmaceutical industry extend to vaccine manufacturing, where the quality of water utilized directly impacts the final product. This paper explores the significance of water purity in vaccine production, detailing the specific standards, purification processes, and regulatory frameworks that govern the use of ultra-pure water in creating life-saving vaccines.

The Essentiality of Water Purity in Vaccine Manufacturing: Ensuring Safety and Efficacy

Abstract:

Water, a fundamental component in vaccine production, plays a critical role in ensuring the safety, potency, and purity of vaccines. The stringent requirements for water purity in the pharmaceutical industry extend to vaccine manufacturing, where the quality of water utilized directly impacts the final product. This paper explores the significance of water purity in vaccine production, detailing the specific standards, purification processes, and regulatory frameworks that govern the use of ultra-pure water in creating life-saving vaccines.

Introduction:

Vaccines, indispensable in safeguarding global health, demand meticulous attention to quality and safety throughout their production. Water, an often overlooked but crucial ingredient, serves as a key component in various stages of vaccine manufacturing, including formulation, cleaning, and as a raw material. The stringent demands for water purity in vaccine production stem from the necessity to maintain the integrity and efficacy of these life-saving medications.

Water Quality Requirements in Vaccine Manufacturing:

- Purified Water and Water for Injection (WFI):

Vaccine manufacturing adheres to stringent standards for water quality, typically relying on Purified Water (PW) and Water for Injection (WFI). These water classifications require a multi-step purification process to eliminate impurities, ensuring water of exceptional purity.

- Microbial Control:

Water used in vaccine production must be devoid of microbial contaminants. Rigorous microbial control measures, including UV disinfection, ultrafiltration, and reverse osmosis, are employed to ensure microbial reduction to acceptable levels.

Impact on Vaccine Safety and Efficacy:

- Contaminant-Free Formulations:

Impurities in water can compromise the stability and efficacy of vaccine formulations. Any presence of contaminants could affect the potency and safety of the final vaccine product, potentially rendering it ineffective or unsafe for use.

- Regulatory Compliance:

Regulatory agencies, such as the United States Pharmacopeia (USP) and the European Pharmacopoeia (EP), set stringent standards for water quality in pharmaceuticals, including vaccines. Compliance with these standards is essential to ensure the safety and efficacy of vaccines produced.

Water Purification Processes in Vaccine Manufacturing:

- Distillation:

Historically, distillation has been a primary method to produce WFI, involving heating water to vaporize and condense it into a separate container, eliminating impurities. However, modern methods have evolved to include more advanced purification techniques.

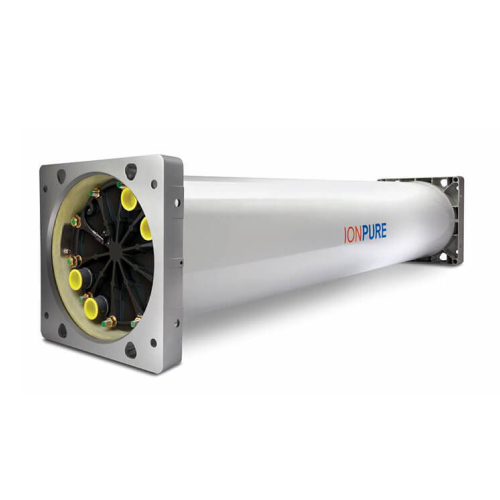

- Reverse Osmosis and Ultrafiltration:

These processes involve the use of semi-permeable membranes to remove contaminants, ions, and particles, ensuring water of high purity suitable for vaccine production.

Conclusion:

The purity of water used in vaccine manufacturing is not just a technicality; it is a cornerstone of vaccine safety and efficacy. Stringent purification processes and adherence to rigorous standards are essential to maintain the integrity of vaccines. The assurance of ultra-pure water in vaccine production underscores the commitment of pharmaceutical companies to produce vaccines of the highest quality, ensuring their potency, safety, and efficacy in safeguarding global health. Regulatory oversight, technological advancements, and a steadfast dedication to water purity remain indispensable in the continued quest to create safe and effective vaccines for global immunization efforts.