Recent Posts

Water Treatment in Hydrogen Production

As the world pivots towards renewable energy sources, hydrogen emerges as a promising contender in the quest for sustainable solutions. This clean, versatile fuel holds immense potential to revolutionize various sectors, from transportation to industrial processes. However, unlocking the full potential of hydrogen production requires a keen focus on efficient water treatment—a cornerstone of the hydrogen production process.

The Vital Role of Water Treatment in Hydrogen Production

As the world pivots towards renewable energy sources, hydrogen emerges as a promising contender in the quest for sustainable solutions. This clean, versatile fuel holds immense potential to revolutionize various sectors, from transportation to industrial processes. However, unlocking the full potential of hydrogen production requires a keen focus on efficient water treatment—a cornerstone of the hydrogen production process.

The Hydrogen Revolution

Hydrogen, hailed as the ‘fuel of the future,’ offers a clean and abundant energy source with zero emissions at the point of use. One of the primary methods of producing hydrogen involves electrolysis, a process that separates water molecules into hydrogen and oxygen using electricity.

The Significance of Water Treatment

Water, the fundamental raw material in electrolysis-based hydrogen production, plays a crucial role in the efficiency and sustainability of the process. Purified water free from impurities such as dissolved minerals, particulate matter, and organic compounds is essential to ensure the longevity and optimal performance of electrolysis systems.

Importance of Purified Water

- Maximizing Electrolyzer Efficiency

Impurities in water can negatively impact the efficiency of electrolyzers used in hydrogen production. Minerals and particulates can accumulate on electrodes, hindering the electrolysis process, reducing efficiency, and increasing energy consumption.

- Prolonging Equipment Lifespan

Corrosion, scaling, and fouling caused by impurities in water can damage critical components of electrolysis equipment. Proper water treatment not only ensures consistent performance but also extends the lifespan of expensive equipment, reducing maintenance costs.

Water Treatment Methods

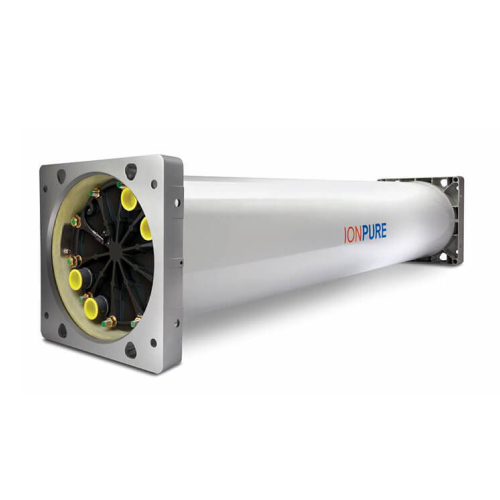

- Reverse Osmosis (RO) and Deionization

RO systems effectively remove dissolved impurities and contaminants, providing high-quality water essential for electrolysis. Deionization complements RO by further purifying water, removing ions that could hinder the electrolysis process.

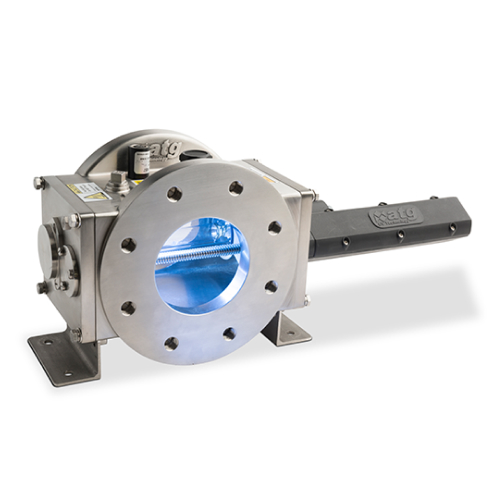

- Filtration and Pre-Treatment

Filtration processes, including mesh filtration and activated carbon filtration, help eliminate suspended solids and organic matter, preventing fouling and enhancing the efficiency of subsequent purification methods.

Advancements and Sustainability

Continual advancements in water treatment technologies aim to enhance efficiency and sustainability in hydrogen production. Researchers focus on developing cost-effective and energy-efficient purification methods, aiming to minimize the environmental footprint of the water treatment process.

Conclusion

Water treatment stands as a linchpin in the realm of hydrogen production, ensuring the purity and quality of water vital for efficient electrolysis. As the world races towards a hydrogen-powered future, the optimization of water treatment processes is crucial for unlocking the full potential of this clean energy source.

Efforts to refine water treatment methods align with the broader goal of achieving sustainable and efficient hydrogen production. Embracing innovative water treatment technologies will undoubtedly pave the way for a more eco-friendly and economically viable hydrogen economy, catalyzing a cleaner, greener future for generations to come.